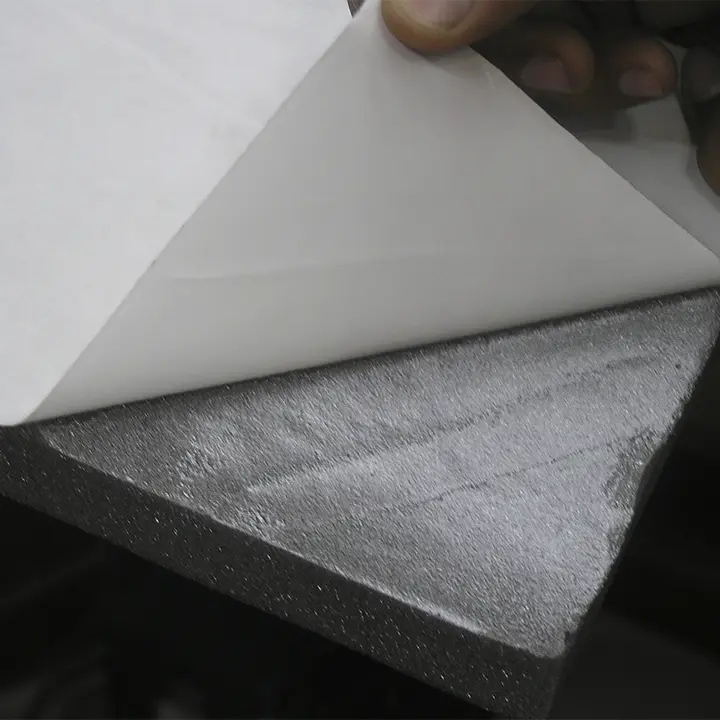

Self Adhesive Backing Acoustic Foam

Product Code: FV-Acoustics-SAF

We offer Self-Adhesive Acoustic Foam Sheets in a wide variety of shapes, sizes, and colors, tailored to meet diverse industrial, commercial, and residential acoustic applications. These foams are available in both fire-retardant and non-fire-retardant grades, providing flexible solutions to meet safety requirements and regulatory standards.

Made from open-cell flexible polyurethane, these acoustic foams are specifically designed to maximize sound absorption and optimize acoustic performance. The open-cell structure allows sound waves to penetrate the foam, converting sound energy into thermal energy, which significantly reduces noise, reverberation, and echo.The availability of different profiles and shapes, including pyramids, wedges, and egg crate designs, further enhances the foam’s effectiveness by increasing the surface area and improving sound diffusion.

Description

This makes them highly suitable for applications where precise acoustic control is required, such as recording studios, home theatres, vehicle interiors, sound-insulating cabins, partition walls, industrial machinery enclosures, and electrical apparatus housings. The variation in shape, depth, and thickness allows the foam to be customized for specific frequency absorption and room acoustics, ensuring optimal performance in any environment.

A key feature of our products is the self-adhesive backing, which simplifies installation and saves time. Customers can easily remove the release liner and apply the foam directly to the required surface without the need for additional adhesives or fasteners. This combination of coating, shape design, and adhesive backing not only improves installation convenience but also enhances the foam’s lifespan, durability, and resistance to dirt, moisture, oils, and other contaminants in industrial environments.

Our acoustic foams are available in densities ranging from 28 to 60 kg/m³ (fire-retardant grades) and can be cut or processed to any required size. We offer customization in coating thickness, adhesive strength, shape, and color, allowing the product to meet the specific aesthetic and functional requirements of each project. The sheets are securely packaged in black LDPE and HDPE bags to ensure safe delivery, with a standard lead time of 8 days after order confirmation.

With the support of our Research & Development (R&D) team, we can develop custom coatings and specialized foam options to suit unique industrial and acoustic applications. By combining open-cell structure, optimized profiles, and self-adhesive backing, our acoustic foam sheets provide a highly effective, durable, and easy-to-install solution for managing sound, reducing noise, and enhancing acoustic performance across a wide range of environments.

Fire Retardant Certification Options: UL-94, CA-117, BS5852, FMVSS302

Note: We are in a position to offer Acoustic Foams with a wide range of options. We request you to please drop your inquiries at info@foamvilla.com enabling us to serve you promptly.

Absorption of sound energy therefore used in Sound Insulating Cabins, Vehicle Cabs, Mechanical Engineering, Partition Walls, Electrical Apparatus Construction, Enclosures etc.

Foam Density: Any required. In regular product, we use 28 to 60 FR grades flexible foam

Foam Type: Fire Retardant

Adhesive Specification: Vary application to application

Size: Any Required

Supply Ability: No Constraint

Packaging: A set of sheets in a Black LDPE sheet than in an HDPE bag

Delivery: Within 8 days once the order is confirmed.

- It enhances product appearance and increases its lifespan.

- Self Adhesive products with the firm adhesive coating offer high quality and are easy to apply.