NVH Solutions, Gaskets & Seals

Polyurethane (PU) foam is a versatile material extensively used in the automotive industry for Noise, Vibration, and Harshness (NVH) control, as well as in the manufacturing of gaskets and seals. Its unique combination of flexibility, durability, and sealing capabilities allows automotive manufacturers to enhance cabin comfort, reduce noise and vibration, and ensure precise sealing in critical systems.

NVH Solutions Using PU Foam

Sound Absorption: Open-cell PU foam effectively absorbs and dampens airborne noise from engines, road surfaces, and wind, contributing to a quieter and more comfortable vehicle cabin.

Vibration Damping: PU foam cushions and isolates vibrations from drivetrain, suspension, and chassis components, minimizing harshness and improving ride quality.

Description

Lightweight Performance: Its low density helps reduce overall vehicle weight while delivering efficient NVH performance, contributing to better fuel efficiency and handling.

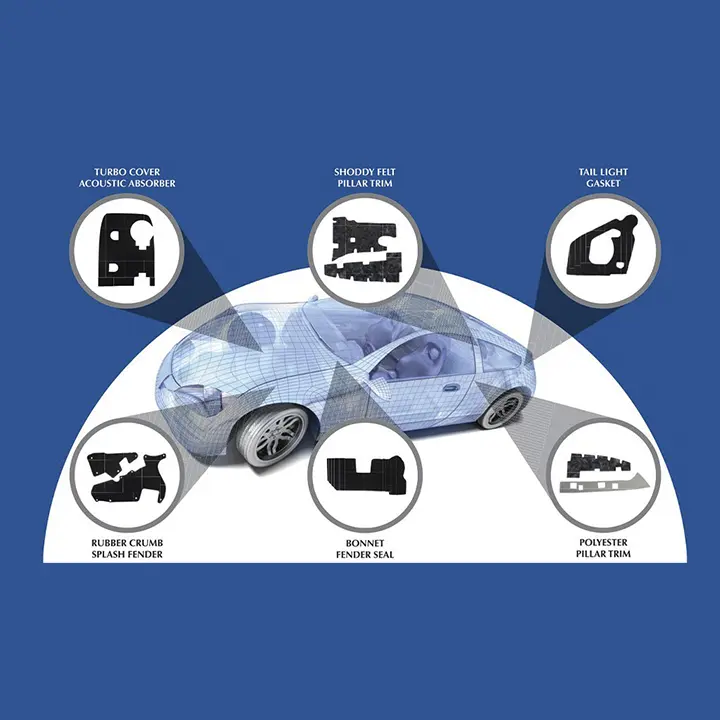

Wide Applications: PU foam is used across multiple automotive components,including door panels,dashboards, wheel arches, engine compartments, and firewall insulation, providing comprehensive noise and vibration control.

Sound Absorption: Open-cell PU foam effectively absorbs and dampens airborne noise from engines, road, and wind, improving cabin quietness.

Vibration Damping: PU foam cushions and isolates vibrations from the drivetrain, suspension, and chassis components to reduce harshness.

Lightweight: Contributes to overall vehicle weight reduction while providing effective NVH performance.

Applications: Used in door panels, dashboards, wheel arches, engine compartments, and firewall insulation.

Sealing Performance: PU foam provides excellent compression and recovery, ensuring airtight and watertight seals in doors, windows, trunks, and HVAC systems.

Flexibility & Durability: Maintains sealing integrity under varying temperatures, pressures, and repeated use.

Custom Profiles: Can be molded or extruded into custom gasket shapes for precise fit and function.

Chemical Resistance: Resistant to oils, fuels, and other automotive fluids, enhancing lifespan.

Benefits of Polyurethane Foam for NVH, Gaskets & Seals

- Excellent resilience and compression set resistance.

- Versatile in density and firmness to suit specific applications.

- Easy to mold and fabricate for complex geometries.

- Enhances overall vehicle comfort, safety, and durability.