Automotive Sound Deadening

Polyurethane (PU) foam is widely used in the automotive industry for its exceptional ability to enhance cabin acoustics, reduce road noise, and provide a more comfortable driving experience. Its lightweight structure, versatility, and cost-effectiveness make it an ideal material for modern vehicle design and manufacturing. PU foam is incorporated into various parts of the vehicle—such as door panels, headliners, dashboards, trunk liners, floor sections, wheel arches, and seating—to effectively absorb sound and dampen vibrations.

By minimizing road noise, engine resonance, and exterior disturbances, PU foam helps create a quieter and more peaceful cabin environment for passengers. Beyond acoustic benefits, polyurethane foam also plays a significant role in thermal insulation, helping regulate interior temperature and reducing the load on the vehicle’s HVAC system. Its ability to be molded into complex shapes allows seamless integration into different automotive components without adding unnecessary weight, which further contributes to fuel efficiency and overall vehicle performance.

Description

Offering a balance of durability, flexibility, and performance, PU foam remains a preferred material for automotive manufacturers seeking reliable sound deadening, vibration control, and comfort-enhancing solutions

Types of PU Foam Used for Automotive Sound Insulation

| Foam Type | Properties | Typical Use |

| Open-Cell PU Foam | Highly porous, absorbs airborne noise | Headliners, doors, panels |

| Closed-Cell PU Foam | Dense, blocks both air and vibration | Floor insulation, engine bay |

| Reticulated PU Foam | Engineered for breathability and targeted frequency control | HVAC and interior acoustics |

| Multi-Layer Composite Foam | PU foam with barrier films or aluminum foil | Engine covers, heat + sound blocks |

Common Sound Issues Addressed

| Noise Type | Solution |

| Engine and drivetrain hum | Closed-cell PU foam barriers under the hood |

| Tire and road noise | Underbody floor insulation with PU foam backing |

| Wind noise | Door seal fillers and A-pillar acoustic foam |

| Cabin echo & vibration | Open-cell foam in roofliner, seats, and dash |

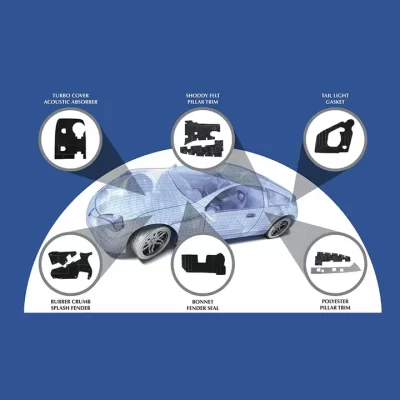

Key Automotive Applications of PU Foam for Acoustics

Headliners & Roof Panels: PU foam reduces rain impact noise and airborne sound transmission from the roof.

Door Panels & Pillars: Applied as filler or backing to absorb road and wind noise, blocks sound transmission from exterior to cabin.

Flooring & Underbody: Used beneath carpets or floor mats to dampen engine, exhaust, and road vibrations.

Dashboards & Instrument Panels: Controls buzz, squeak, and rattle (BSR) noises using molded foam inserts.

Engine Compartment (Acoustic Barriers): PU foam combined with foil layers insulates cabin from engine noise and heat.

Wheel Arches & Trunk Liners: Blocks tire and road noise at the source.

Benefits of PU Foam in Automotive Acoustics

Effective Noise Absorption: Controls wide frequency ranges including mid and high frequencies.

Lightweight & Flexible: Ideal for modern vehicle design and fuel economy standards.

Thermal Insulation Properties: Offers temperature stability in engine and interior zones.

Custom Moldability: Can be shaped for trim parts, dashboards, and hidden cavities.

Cost-Effective: Affordable alternative to heavier or more complex soundproofing materials.

- ISO 3795 / FMVSS 302: Flammability standards for automotive interior foam.

- OEM specifications: Custom formulations for NVH (Noise, Vibration, Harshness) control.

- RoHS / REACH compliance: For environmental and chemical safety.