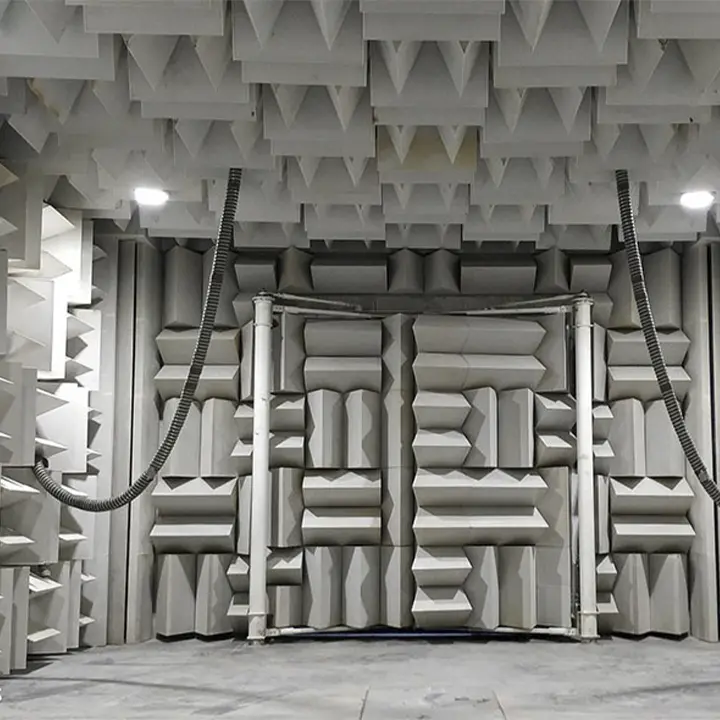

Testing Rooms

Polyurethane (PU) foam is extensively used in testing rooms and sound measurement chambers to create controlled acoustic environments. These rooms require precise sound control to ensure accurate testing, analysis, and measurement of products and equipment. PU foam serves as a lightweight, flexible, and highly effective solution for absorbing sound and eliminating unwanted reflections.

Why PU Foam is Ideal for Testing Rooms

High Sound Absorption – PU foam effectively absorbs mid-to-high frequency noise, reducing reflections and standing waves in the room.

Lightweight & Flexible – Easy to install on walls, ceilings, and panels of various shapes and sizes.

Durable & Long-Lasting – Maintains its acoustic performance over time without sagging or degradation.

Description

Cost-Effective Solution – Provides professional-level acoustic control at a fraction of the cost of heavy traditional materials.

By using PU foam in testing rooms, manufacturers and researchers can achieve precise, reliable, and repeatable acoustic measurements, ensuring that products meet the highest standards of performance and quality.

Types of PU Acoustic Foam Used

| Foam Type | Structure | Function |

| Wedge Foam Panels | Angled cuts | Diffuses sound, reduces standing waves |

| Pyramid Foam Panels | 3D peaks | Broadband absorption and aesthetic appearance |

| Flat Panels (Backer Foam) | Smooth | Used as base layer or under composite structures |

| Custom Molded Panels | Shaped to spec | Engineered for walls, ceilings, or rotating platforms |

Why Use PU Foam in Automotive Sound Testing Rooms?

Sound Absorption: PU foam’s open-cell structure absorbs mid-to-high-frequency sound waves, preventing reflections that can distort test results.

Echo & Reverberation Control: Wedge- or pyramid-shaped PU foam reduces reverberation time, ensuring accuracy during microphone and acoustic sensor testing.

Improves Measurement Precision: Essential for NVH (Noise, Vibration, Harshness) analysis of engines, tires, interiors, and electronic components.

Supports Standardized Testing Conditions: Helps meet ISO and SAE acoustic testing standards by maintaining consistent room acoustics.

Applications in Automotive Acoustic Labs

- Engine and Powertrain Noise Testing

- Speaker and In-Car Audio System Testing

- Electric Vehicle Motor Whine Analysis

- Door Closure and Seal Noise Evaluation

- Material and Component Noise Characterization

- Interior cabin NVH simulations

Technical Properties of PU Acoustic Foam

| Property | Typical Range / Value |

| Density | 25–40 kg/m³ (1.5–2.5 lb/ft³) |

| NRC (Noise Reduction Coefficient) | 0.75–1.00 depending on thickness |

| Fire Resistance | UL 94 HF-1 / FMVSS 302 / ISO 3795 compliant |

| Frequency Range | Effective from 500 Hz to 5000+ Hz |

| Shape Thickness | 2–6 inches (wedge/pyramid) |

Advantages of PU Foam in Automotive Sound Testing Rooms

- High acoustic performance for critical audio measurements

- Lightweight and easy to install on walls, ceilings, and floors

- Customizable sizes, shapes, and colors

- Fire-rated and lab-tested for industrial environments

- More affordable than fiberglass or mineral wool for mid/high frequencies