Sunvisor

SunvisorPolyurethane (PU) foam is extensively used in automotive sun visors to provide the perfect balance of support, comfort, and durability. Acting as a core material, PU foam offers structural integrity while maintaining lightweight properties, which is essential for vehicle efficiency and ease of use.

Key Benefits and Applications

Structural Support: PU foam gives sun visors a firm yet slightly flexible core, ensuring they retain shape over time without sagging or deforming.

Cushioning & Comfort: The foam layer provides a soft surface that enhances tactile comfort while handling the visor.

Surface Smoothness & Finish: PU foam allows manufacturers to achieve smooth, aesthetically appealing surfaces, whether covered with fabric, vinyl, or leather.

Seat Covers Foam

Seat Covers FoamPolyurethane (PU) foam is a vital material in automotive seat cover systems, serving as the cushioning layer beneath upholstery fabrics. Its versatility, comfort, and durability make it indispensable for enhancing the seating experience in vehicles, whether for daily commutes, long drives, or luxury applications.

Key Applications and Benefits of PU Foam in Automotive Seat Covers

- Cushioning Layer: PU foam acts as the primary padding beneath seat covers, absorbing pressure and providing a comfortable seating surface for drivers and passengers.

- Ergonomic Support: By adjusting foam density and firmness, manufacturers can target support to specific body zones, including lumbar, thigh, and back areas, promoting proper posture and reducing fatigue.

Polishing Foam

Polishing FoamPolyurethane (PU) Foam Application in Automotive Polishing

Polyurethane (PU) foam plays a critical role in the automotive polishing industry, serving as the primary material for polishing pads and buffing accessories. Its unique combination of softness, durability, and resilience ensures optimal performance, delivering smooth, flawless finishes while protecting vehicle surfaces during polishing and detailing processes.

Key Applications and Benefits of PU Foam in Automotive Polishing

- Polishing Pads: PU foam is expertly shaped into pads that can be mounted on rotary or dual-action polishers. These pads allow for controlled application of compounds, polishes, and waxes, ensuring even coverage and consistent results.

- Surface Protection: The inherent softness of PU foam ensures gentle abrasion, effectively removing oxidation, swirl marks, fine scratches, and minor surface imperfections without damaging paintwork.

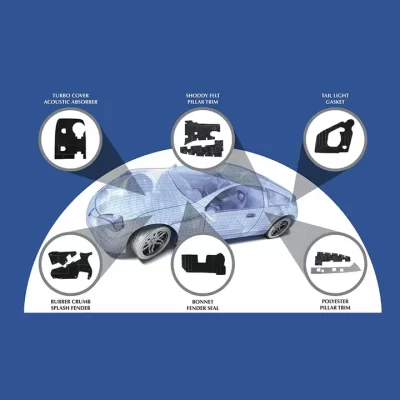

NVH Solutions, Gaskets & Seals

NVH Solutions, Gaskets & Seals

NVH Solutions, Gaskets & Seals

NVH Solutions, Gaskets & SealsPolyurethane (PU) foam is a versatile material extensively used in the automotive industry for Noise, Vibration, and Harshness (NVH) control, as well as in the manufacturing of gaskets and seals. Its unique combination of flexibility, durability, and sealing capabilities allows automotive manufacturers to enhance cabin comfort, reduce noise and vibration, and ensure precise sealing in critical systems.

NVH Solutions Using PU Foam

Sound Absorption: Open-cell PU foam effectively absorbs and dampens airborne noise from engines, road surfaces, and wind, contributing to a quieter and more comfortable vehicle cabin.

Vibration Damping: PU foam cushions and isolates vibrations from drivetrain, suspension, and chassis components, minimizing harshness and improving ride quality.

Interior Trim And Upholstery

Interior Trim And Upholstery

Interior Trim And Upholstery

Interior Trim And UpholsteryPolyurethane (PU) foam is a cornerstone material in automotive interior trim and upholstery, providing comfort, cushioning, and aesthetic appeal. Its versatility, durability, and customizable properties make it ideal for a wide range of interior components, enhancing both passenger comfort and vehicle design.

Key Applications of PU Foam in Interior Trim and Upholstery

- Seat Cushions and Backs: PU foam improves seating comfort by providing ergonomic support and even pressure distribution. High-resilience foams retain their shape over extended use, and multi-density designs allow different firmness zones within a single seat, optimizing lumbar, thigh, and back support.

- Door Panels and Armrests: Integral skin PU foam creates soft, durable surfaces with excellent abrasion resistance, delivering a premium feel and tactile comfort while enhancing overall interior aesthetics.

Insulation

InsulationPolyurethane (PU) foam is extensively used in the automotive industry as a highly effective insulation material, providing thermal control, acoustic dampening, and vibration reduction. Its lightweight, versatile, and durable properties make it an ideal choice for enhancing passenger comfort, improving cabin quietness, and boosting overall vehicle performance.

Key Applications of PU Foam in Automotive Insulation

Thermal Insulation: PU foam is widely used to reduce heat transfer from the engine, exhaust system, and external environment. It is commonly applied in floor panels, roof liners, and firewall insulation to maintain a stable cabin temperature. By improving thermal insulation, PU foam enhances HVAC efficiency, ensures passenger comfort, and helps optimize energy consumption.

Headrests and Armrests

Headrests and ArmrestsPolyurethane (PU) foam is a versatile and essential material in automotive interiors, particularly in headrests and armrests, where comfort, durability, and ergonomic design are critical. Its moldability, resilience, and long-lasting properties make it ideal for delivering superior passenger comfort and maintaining safety standards.

Armrests: In automotive armrests, PU foam provides a soft yet supportive surface that enhances passenger comfort during long drives. Many armrests use integral skin PU foam, which combines a cushioned inner core with a durable outer layer. This construction ensures a smooth, wear-resistant surface that withstands scratches, environmental exposure, and frequent use, while maintaining a premium look and feel.

Headrests: For headrests, PU foam plays a dual role in comfort and safety. High-resilience (HR) PU foam is typically used to absorb impact forces during collisions while providing consistent support for the head and neck during normal driving. The foam’s excellent recovery properties ensure that the headrest retains its shape and effectiveness over time, contributing to ergonomic support and overall occupant safety.

Automotive Flooring

Automotive FlooringPolyurethane (PU) foam is a versatile material widely used in automotive flooring to enhance comfort, insulation, and noise reduction. Its lightweight, durable, and flexible properties make it ideal for creating a quieter, more comfortable cabin environment while contributing to overall vehicle performance.

Key Applications of PU Foam in Automotive Flooring

Under-Carpet Padding: PU foam acts as a cushioning layer beneath carpets, improving seating comfort and ergonomics while providing a soft, supportive feel underfoot.

Sound Deadening Layer: Open-cell and flexible PU foams help reduce road noise, engine vibrations, and structural rattles, effectively addressing NVH (Noise, Vibration, Harshness) concerns in passenger cabins.

Thermal Insulation: PU foam provides a barrier against heat transfer from the engine bay, exhaust system, or external environment, helping maintain a comfortable cabin temperature and improving HVAC efficiency.

Filtration

FiltrationPolyurethane (PU) foam is widely used in automotive filtration systems due to its open-cell, reticulated structure that provides excellent airflow while effectively trapping dust, debris, and other contaminants. Lightweight, flexible, chemically resistant, and highly customizable, PU foam is an ideal material for both air and fluid filtration applications in modern vehicles.

Key Applications of PU Foam in Automotive Filtration

Engine Air Filters: PU foam is often used as a primary or secondary filtration layer in engine air filters. It efficiently traps coarse particles, protecting the engine from dust and debris while enhancing performance and longevity.

Cabin Air Filters: In HVAC systems, PU foam captures dust, pollen, and airborne particles, improving cabin air quality and passenger comfort. Its flexibility allows it to conform to various filter shapes, maximizing filtration efficiency.

Automotive Cushioning

Automotive CushioningPolyurethane (PU) foam is a critical material in automotive cushioning, offering an ideal combination of comfort, durability, and cost-effectiveness. Its versatility allows automotive designers and manufacturers to create seating, interior components, and ergonomic solutions that meet safety, comfort, and aesthetic requirements.

Applications of PU Foam in Automotive Cushioning

Seats (Cushions & Backrests): PU foam serves as the primary cushioning material in seat cushions and backrests, providing comfort, ergonomic support, and long-term durability. High-resilience (HR) foams maintain shape under prolonged use, while tailored foam densities can optimize support across different zones, such as lumbar and thigh areas.

Headrests: PU foam in headrests functions as an energy-absorbing padding that helps reduce whiplash risk during collisions while also offering comfort during normal driving conditions.

Air Filter Seals

Air Filter SealsFlexible foam is widely used in air filter seals across automotive, industrial, and HVAC systems due to its excellent sealing performance, compressibility, and chemical resistance. It plays a critical role in ensuring that air filtration systems function efficiently and reliably.

Key Functions of Flexible Foam in Air Filter Seals

Air Leak Prevention: Flexible foam provides a tight, consistent seal between the filter housing and filter media, preventing unfiltered air from bypassing the filter. This ensures that all airflow passes through the filter media, maintaining optimal air quality and system efficiency.

Vibration Damping: Flexible foam absorbs vibrations generated by engines, blowers, or other mechanical systems. By acting as a cushioning layer, it reduces wear and tear on filter assemblies and other components, prolonging service life.