Laser Quilted Foam Products

Laser Quilted Foam Products

Laser Quilted Foam Products

Laser Quilted Foam ProductsProduct Code: FV-Laminates-Laser

We offer Ultrasonic Quilted Products processed using the latest technology through which fabric is welded and stick together without thread and needle. In the process of Polyester Fiber, Foam is melted by ultrasound which bonds the fabric, base material, the non-woven filling altogether.

We offer Laser quilted products with several quilting patterns and choices & also do customized designs as per specific customer requirements.

Product Origin: Across the Globe.

Specification:

Product Width: 60 inches to 80 inches

Lamination Type: One Side and Two Side

Packaging: Each Roll in an HM plastic sheet and then in an HDPE bag.

Delivery: Within a week once the order is confirmed.

Glue Laminated Foam Products

Glue Laminated Foam Products

Glue Laminated Foam Products

Glue Laminated Foam ProductsProduct Code: FV-Laminates-Glue

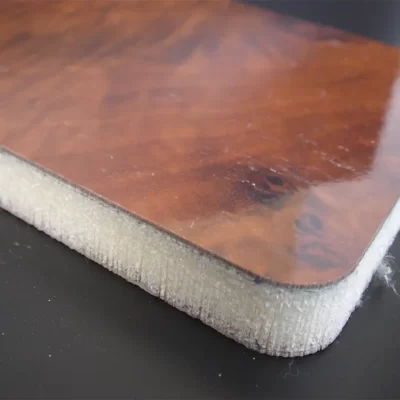

We offer Glue Laminated Foam Products processed through laminating a wide range of Foams (flexible, polyester, polyether, cross-linked & polyethylene) to a variety of other substrates, including films, paper, and fabric through the Glue lamination process to meet a broad range of industrial applications.Glue laminated foam products are considered better than flame lamination products as they carry a better constant coating which is hard to gain through the flame lamination process.

Product Origin: Across the Globe.

Specification:

Foam Density: Any Required (Ranging from type of foam)

Film/Fabric Type: Any Required

Product Width: 52 inches to 80 inches

Lamination Type: One Side and Two Side

Flame Laminated Foam Products

Flame Laminated Foam Products

Flame Laminated Foam Products

Flame Laminated Foam ProductsProduct Code: FV-Laminates-Flame

We offer a wide range of Flame Laminated Products processed through bonding flexible foams (both polyester and polyether) to a variety of substrates like films, fabrics, and paper as per specific customer and end application requirements.Flame lamination is considered as the cheapest & fastest method of lamination.

It helps in bonding a wide range of material to Polyurethane foam, the process involves passing foam over a flame, creating a thin layer of molten polymer. The fabric/film or paper is immediately pressed against the foam while it is still in the molten state under controlled pressure and tensile offering high bonding strength to the laminated product.