Acoustic Melamine Foams

Acoustic Melamine FoamsProduct Code: FV-Melamine-Acoustic

Melamine foam sheets are an advanced solution for acoustic wall applications, providing superior sound absorption, lightweight construction, and inherent fire-resistant properties. These foams are widely used in processing acoustic walls and panels, often in combination with gypsum plasterboard, chipboard, plywood, or metal, to create room dividers and partition walls.

This composite approach allows architects and designers greater flexibility, offering aesthetic appeal while replacing traditional mineral or glass fibers used primarily for acoustic performance.Made from open-cell melamine resin, these sheets efficiently reduce echoes, reverberation, and ambient noise across a broad range of frequencies, creating quieter, more comfortable indoor environments.Their low density and open-cell structure enable easy handling and installation on walls, ceilings, or partitions without adding significant weight.

Melamine Foam Cleaners

Melamine Foam CleanersProduct Code: FV- Melamine- Cleaner

We offer low-density, open-cell Melamine Foam cleaners in a variety of sizes and shapes, designed for a wide range of cleaning applications. Made from highly porous melamine resin, this foam acts as an ultra-fine abrasive, effortlessly removing dirt, stains, grease, crayon, marker pen, and other stubborn marks from walls, tiles, glass, kitchen appliances, footwear, automotive interiors, and more.

Its open-cell microstructure allows it to penetrate tiny grooves, pits, and textured surfaces, making it highly effective in areas that are difficult to clean with conventional sponges or cloths.Melamine Foam cleans surfaces primarily with water, reducing or eliminating the need for harsh chemicals. It works by physically lifting and trapping dirt, providing a streak-free finish while minimizing scrubbing effort. Lightweight, durable, and easy to handle, it is safe for most hard, painted, or coated surfaces, although caution is recommended on delicate or glossy finishes.

Cylindrical Shape Melamine Foam

Cylindrical Shape Melamine Foam

Cylindrical Shape Melamine Foam

Cylindrical Shape Melamine FoamProduct Code: FV-Melamine-Cylinders

Cylinder Shape Melamine Foam is specially designed for acoustic environments requiring effective noise reduction and sound absorption. These foams, made from lightweight, open-cell melamine resin, provide excellent sound absorption across both low and high frequencies. The cylindrical profile, with greater circumference than other shapes, allows the foam to be suspended or hanged, making it ideal for auditoriums, studios, offices, industrial facilities, and other spaces requiring vertical or suspended acoustic treatment.

Sound absorption depends on factors such as cylinder diameter, length, and the angle of sound wave incidence, so proper consultation with acoustic experts ensures optimal performance.The open-cell structure captures and dissipates sound energy efficiently, reducing echoes, reverberation, and ambient noise.Their lightweight design ensures minimal structural load when hung from ceilings or mounted on frames.

Composite Melamine Foam Panels

Composite Melamine Foam Panels

Composite Melamine Foam Panels

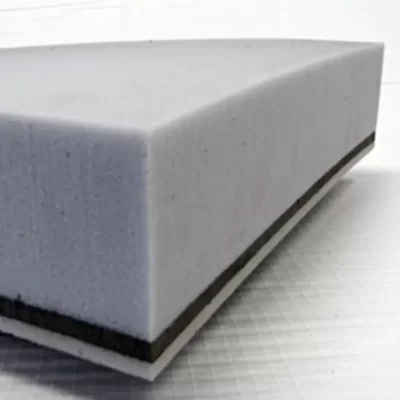

Composite Melamine Foam PanelsProduct Code: FV-Melamine-Composite Panels

Composite Melamine Foam Panels are advanced acoustic solutions designed for environments where sound absorption, vibration control, and reduction of sound transmission are critical. These foams are made from melamine resin, known for its lightweight, open-cell structure, excellent sound absorption, and inherent fire retardant properties. For demanding industrial applications, melamine foam is processed in a sandwich structure with high-density mass-loaded vinyl noise barriers, enhancing both mechanical strength and noise-blocking capability.

This makes them ideal for high-noise environments such as heavy machinery rooms, metalworking plants, and industrial enclosures.The foam’s open-cell network efficiently absorbs and diffuses sound across a wide frequency range, reducing echoes, reverberation, and ambient noise.Composite layers, including non-woven fabrics, polyurethane, or other polymeric coatings, further improve durability, structural stability, and functional versatility.

Laser Quilted Foam Products

Laser Quilted Foam Products

Laser Quilted Foam Products

Laser Quilted Foam ProductsProduct Code: FV-Laminates-Laser

We offer Ultrasonic Quilted Products processed using the latest technology through which fabric is welded and stick together without thread and needle. In the process of Polyester Fiber, Foam is melted by ultrasound which bonds the fabric, base material, the non-woven filling altogether.

We offer Laser quilted products with several quilting patterns and choices & also do customized designs as per specific customer requirements.

Product Origin: Across the Globe.

Specification:

Product Width: 60 inches to 80 inches

Lamination Type: One Side and Two Side

Packaging: Each Roll in an HM plastic sheet and then in an HDPE bag.

Delivery: Within a week once the order is confirmed.

Glue Laminated Foam Products

Glue Laminated Foam Products

Glue Laminated Foam Products

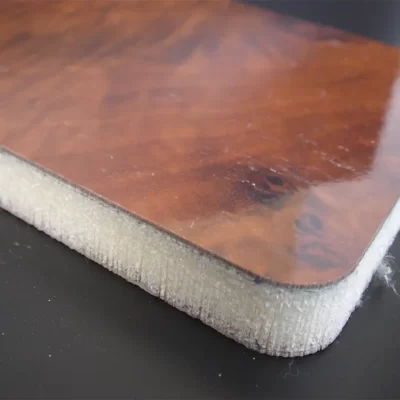

Glue Laminated Foam ProductsProduct Code: FV-Laminates-Glue

We offer Glue Laminated Foam Products processed through laminating a wide range of Foams (flexible, polyester, polyether, cross-linked & polyethylene) to a variety of other substrates, including films, paper, and fabric through the Glue lamination process to meet a broad range of industrial applications.Glue laminated foam products are considered better than flame lamination products as they carry a better constant coating which is hard to gain through the flame lamination process.

Product Origin: Across the Globe.

Specification:

Foam Density: Any Required (Ranging from type of foam)

Film/Fabric Type: Any Required

Product Width: 52 inches to 80 inches

Lamination Type: One Side and Two Side

Flame Laminated Foam Products

Flame Laminated Foam Products

Flame Laminated Foam Products

Flame Laminated Foam ProductsProduct Code: FV-Laminates-Flame

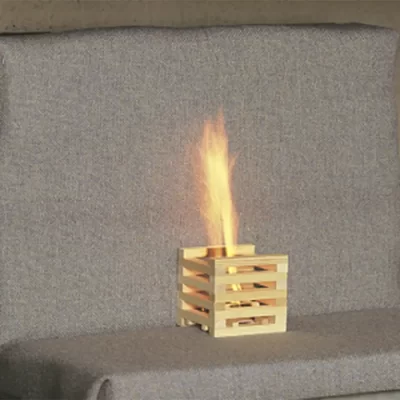

We offer a wide range of Flame Laminated Products processed through bonding flexible foams (both polyester and polyether) to a variety of substrates like films, fabrics, and paper as per specific customer and end application requirements.Flame lamination is considered as the cheapest & fastest method of lamination.

It helps in bonding a wide range of material to Polyurethane foam, the process involves passing foam over a flame, creating a thin layer of molten polymer. The fabric/film or paper is immediately pressed against the foam while it is still in the molten state under controlled pressure and tensile offering high bonding strength to the laminated product.

UL-94 Standard FR Foam

UL-94 Standard FR FoamProduct Code: FV-Fire Retardants UL

We offer UL-94 certified fire retardant flexible polyurethane foams, designed to provide enhanced fire safety without compromising acoustic performance or cushioning properties.

The UL-94 standard, established by Underwriters Laboratories (USA), evaluates the flammability of plastic materials in devices and appliances, measuring a material’s tendency to either extinguish or propagate flame once ignited. Our foams are widely used in automotive interiors, HVAC systems, industrial enclosures, and acoustic applications, providing reliable fire protection in both residential and industrial settings.

Triss Free FR Foam

Triss Free FR FoamProduct Code: FV-Fire Retardants-TF

At Foamvilla, we offer Triss Free Fire Retardant (FR) Flexible Foam, specially formulated without tris(2-chloroethyl) phosphate (TCEP) and other harmful halogenated flame retardants, making it a safer and environmentally friendly alternative to conventional FR foams. TCEP, historically used in flexible foam production, has been associated with serious health hazards, particularly in children, including memory loss, impaired motor skills, lower IQ, and increased cancer risk.

Keeping this in mind, our Triss Free Foams are designed to provide all the benefits of fire retardancy and cushioning while adhering to modern safety and regulatory standards, especially for products intended for children and sensitive applications. These foams are manufactured using polyether or polyester polyurethane bases, maintaining a lightweight structure, excellent durability, flexibility, acoustic absorption, and high cushioning performance.

FMVSS-302 Standard FR Foam

FMVSS-302 Standard FR Foam

FMVSS-302 Standard FR Foam

FMVSS-302 Standard FR FoamProduct Code: FV-Fire Retardants-FMVSS

We offer FMVSS 302 certified fire retardant flexible polyurethane foams, specifically engineered to meet the Federal Motor Vehicle Safety Standard No. 302 (FMVSS 302), which sets flammability requirements for materials used in vehicle interiors, including seat cushions, dashboards, headliners, door panels, and other trim components.

These foams are processed with polyester and polyether polyurethane bases, incorporating special flame retardant additives during foaming to slow down flame spread and allow the foam to self-extinguish, enhancing passenger safety while maintaining flexibility, cushioning, and durability.Our FMVSS 302 foams can be customized in density, thickness, sheet size, color, and are available in flat sheets or profiled designs such as wedge, pyramid, or egg crate to meet acoustic, comfort, or insulation requirements.

CA-117 Standard FR Foam

CA-117 Standard FR FoamProduct Code: FV-Fire Retardants-CA

We offer CA-117 certified fire retardant flexible polyurethane foams, engineered to meet the California Technical Bulletin 117 (TB117) standard, which defines the flammability requirements for foam used in upholstered furniture and seating. This standard tests each upholstery component (except the covering fabric) for resistance to ignition from smoldering cigarettes in a controlled test chamber, measuring the cigarette char length against defined criteria.

Passing this test ensures compliance with fire safety regulations in residential, commercial, and specific international applications.Our CA-117 foams are available in polyester and polyether polyurethane bases, processed with special flame retardant additives during foaming to slow flame spread and allow the material to self-extinguish in case of fire.

BS 5852 Standard FR Foam

BS 5852 Standard FR FoamProduct Code: FV-Fire Retardants-BS

We offer BS 5852 certified fire retardant flexible polyurethane foams, designed to meet the British Standard for assessing the ignitability of single material combinations, such as covers and fillings used in upholstered seating, or complete seating items, when subjected to smoldering cigarettes or flaming ignition sources. This includes thermal outputs ranging from a burning match to the equivalent of four double sheets of full-size newspaper, simulating accidental ignition scenarios in furniture and comfort products.

Our fire retardant foams are available in polyester and polyether polyurethane bases, processed with special flame retardant additives during foaming to ensure compliance with fire code standards.These additives help slow down fire propagation and allow the foam to self-extinguish, providing enhanced safety for both residential and industrial applications.