Quick Dry Memory Foam

Quick Dry Memory FoamProduct Code: FV-Memory-Quick Dry

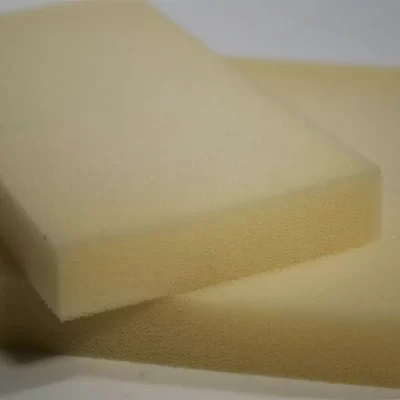

We process Open-Cell, Quick-Dry Memory Foam for applications where rapid drying, cushioning, support, resilience, and slow recovery properties are required. As the name suggests, this foam features a fully open-cell structure that allows excellent air and water flow, enabling moisture to pass through easily.This ensures the foam dries significantly faster than conventional memory foams, preventing water retention and helping maintain hygiene and durability.

Because of its quick-drying capability, this foam is ideal for applications where the material comes in frequent contact with water, such as bath mats and outdoor furniture.Engineered for demanding environments, open-cell quick-dry memory foam retains all the essential qualities of viscoelastic foam—body contouring, pressure relief, and slow recovery—while offering superior breathability and drainage.

Hard Memory Foam

Hard Memory FoamProduct Code: FV-Memory- Hard

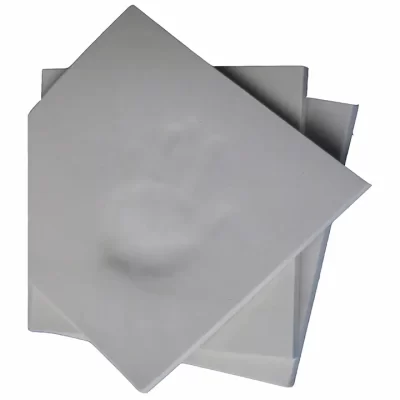

Hard Memory Foam is a specialized viscoelastic polyurethane foam engineered to provide a firmer feel while maintaining the signature slow-recovery and contouring properties of standard memory foam. Processed in both sheet and roll form, it is widely used in industrial applications such as bath mats, carpet underlays, and shoe insole products where enhanced support, structural stability, and controlled compression are essential.

By using specific chemical formulations, memory foam can be produced with a harder feel to meet applications requiring added firmness, durability, and long-lasting performance. These foams are typically manufactured as continuous blocks of 30, 60, or even 120 meters in length. The blocks are then converted into large rings on precision cutting machines, which slice the foam into rolls of any required thickness with excellent uniformity and consistency.

Comfort Memory Foam

Comfort Memory FoamProduct Code: FV-Memory-Comfort

Memory Foam, also known as Viscoelastic or Visco Foam, is a premium flexible polyurethane foam recognized for its unique ability to conform to the body’s shape under heat and pressure and slowly return to its original form once the pressure is released. This molding and contouring characteristic provides uniform support across all body points, reduces pressure on joints, and minimizes the risk of pressure sores.

Due to these comfort-enhancing properties, memory foam is widely used in high-end mattresses,pillows, mattress toppers, medical support products, and specialty upholstery applications.The performance and quality of memory foam are defined by several parameters such as tensile strength, elongation, hardness (ILD), density, tear strength, recovery rate, and rebound properties. These factors determine the foam’s softness, durability, resilience, and suitability for different comfort or medical uses.

Charcoal Memory Foam

Charcoal Memory FoamProduct Code: FV-Memory-Charcoal

We process Charcoal Memory Foam in both sheet and roll form to cater to a wide range of comfort, footwear, bedding, and industrial applications. Using specialized chemical formulations, our memory foams are engineered with different firmness levels, recovery speeds, and bounce-back characteristics. These properties, when combined with activated charcoal infusion, help regulate moisture, temperature, and odor, making Charcoal Memory Foam one of the most hygienic and high-performance comfort materials available.

Our manufacturing capability includes producing continuous foam blocks in lengths of 30 and 60 meters, which are then precisely processed on advanced foam cutting and profiling machinery to derive customized sheet sizes, roll formats, and finished components. The result is a foam that offers superior body contouring, pressure relief, and long-lasting comfort—while maintaining a cleaner, fresher, and more breathable surface due to activated charcoal’s natural odor-absorbing and anti-microbial benefits.

Acoustic Melamine Foams

Acoustic Melamine FoamsProduct Code: FV-Melamine-Acoustic

Melamine foam sheets are an advanced solution for acoustic wall applications, providing superior sound absorption, lightweight construction, and inherent fire-resistant properties. These foams are widely used in processing acoustic walls and panels, often in combination with gypsum plasterboard, chipboard, plywood, or metal, to create room dividers and partition walls.

This composite approach allows architects and designers greater flexibility, offering aesthetic appeal while replacing traditional mineral or glass fibers used primarily for acoustic performance.Made from open-cell melamine resin, these sheets efficiently reduce echoes, reverberation, and ambient noise across a broad range of frequencies, creating quieter, more comfortable indoor environments.Their low density and open-cell structure enable easy handling and installation on walls, ceilings, or partitions without adding significant weight.

Melamine Foam Cleaners

Melamine Foam CleanersProduct Code: FV- Melamine- Cleaner

We offer low-density, open-cell Melamine Foam cleaners in a variety of sizes and shapes, designed for a wide range of cleaning applications. Made from highly porous melamine resin, this foam acts as an ultra-fine abrasive, effortlessly removing dirt, stains, grease, crayon, marker pen, and other stubborn marks from walls, tiles, glass, kitchen appliances, footwear, automotive interiors, and more.

Its open-cell microstructure allows it to penetrate tiny grooves, pits, and textured surfaces, making it highly effective in areas that are difficult to clean with conventional sponges or cloths.Melamine Foam cleans surfaces primarily with water, reducing or eliminating the need for harsh chemicals. It works by physically lifting and trapping dirt, providing a streak-free finish while minimizing scrubbing effort. Lightweight, durable, and easy to handle, it is safe for most hard, painted, or coated surfaces, although caution is recommended on delicate or glossy finishes.

Cylindrical Shape Melamine Foam

Cylindrical Shape Melamine Foam

Cylindrical Shape Melamine Foam

Cylindrical Shape Melamine FoamProduct Code: FV-Melamine-Cylinders

Cylinder Shape Melamine Foam is specially designed for acoustic environments requiring effective noise reduction and sound absorption. These foams, made from lightweight, open-cell melamine resin, provide excellent sound absorption across both low and high frequencies. The cylindrical profile, with greater circumference than other shapes, allows the foam to be suspended or hanged, making it ideal for auditoriums, studios, offices, industrial facilities, and other spaces requiring vertical or suspended acoustic treatment.

Sound absorption depends on factors such as cylinder diameter, length, and the angle of sound wave incidence, so proper consultation with acoustic experts ensures optimal performance.The open-cell structure captures and dissipates sound energy efficiently, reducing echoes, reverberation, and ambient noise.Their lightweight design ensures minimal structural load when hung from ceilings or mounted on frames.

Composite Melamine Foam Panels

Composite Melamine Foam Panels

Composite Melamine Foam Panels

Composite Melamine Foam PanelsProduct Code: FV-Melamine-Composite Panels

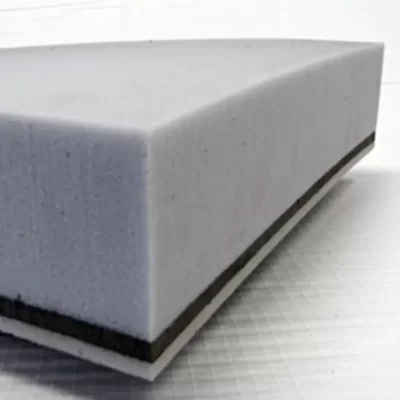

Composite Melamine Foam Panels are advanced acoustic solutions designed for environments where sound absorption, vibration control, and reduction of sound transmission are critical. These foams are made from melamine resin, known for its lightweight, open-cell structure, excellent sound absorption, and inherent fire retardant properties. For demanding industrial applications, melamine foam is processed in a sandwich structure with high-density mass-loaded vinyl noise barriers, enhancing both mechanical strength and noise-blocking capability.

This makes them ideal for high-noise environments such as heavy machinery rooms, metalworking plants, and industrial enclosures.The foam’s open-cell network efficiently absorbs and diffuses sound across a wide frequency range, reducing echoes, reverberation, and ambient noise.Composite layers, including non-woven fabrics, polyurethane, or other polymeric coatings, further improve durability, structural stability, and functional versatility.

Laser Quilted Foam Products

Laser Quilted Foam Products

Laser Quilted Foam Products

Laser Quilted Foam ProductsProduct Code: FV-Laminates-Laser

We offer Ultrasonic Quilted Products processed using the latest technology through which fabric is welded and stick together without thread and needle. In the process of Polyester Fiber, Foam is melted by ultrasound which bonds the fabric, base material, the non-woven filling altogether.

We offer Laser quilted products with several quilting patterns and choices & also do customized designs as per specific customer requirements.

Product Origin: Across the Globe.

Specification:

Product Width: 60 inches to 80 inches

Lamination Type: One Side and Two Side

Packaging: Each Roll in an HM plastic sheet and then in an HDPE bag.

Delivery: Within a week once the order is confirmed.

Glue Laminated Foam Products

Glue Laminated Foam Products

Glue Laminated Foam Products

Glue Laminated Foam ProductsProduct Code: FV-Laminates-Glue

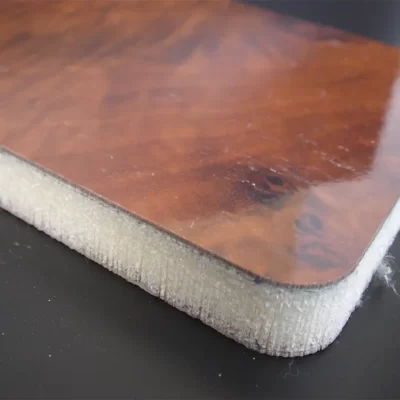

We offer Glue Laminated Foam Products processed through laminating a wide range of Foams (flexible, polyester, polyether, cross-linked & polyethylene) to a variety of other substrates, including films, paper, and fabric through the Glue lamination process to meet a broad range of industrial applications.Glue laminated foam products are considered better than flame lamination products as they carry a better constant coating which is hard to gain through the flame lamination process.

Product Origin: Across the Globe.

Specification:

Foam Density: Any Required (Ranging from type of foam)

Film/Fabric Type: Any Required

Product Width: 52 inches to 80 inches

Lamination Type: One Side and Two Side

Flame Laminated Foam Products

Flame Laminated Foam Products

Flame Laminated Foam Products

Flame Laminated Foam ProductsProduct Code: FV-Laminates-Flame

We offer a wide range of Flame Laminated Products processed through bonding flexible foams (both polyester and polyether) to a variety of substrates like films, fabrics, and paper as per specific customer and end application requirements.Flame lamination is considered as the cheapest & fastest method of lamination.

It helps in bonding a wide range of material to Polyurethane foam, the process involves passing foam over a flame, creating a thin layer of molten polymer. The fabric/film or paper is immediately pressed against the foam while it is still in the molten state under controlled pressure and tensile offering high bonding strength to the laminated product.

UL-94 Standard FR Foam

UL-94 Standard FR FoamProduct Code: FV-Fire Retardants UL

We offer UL-94 certified fire retardant flexible polyurethane foams, designed to provide enhanced fire safety without compromising acoustic performance or cushioning properties.

The UL-94 standard, established by Underwriters Laboratories (USA), evaluates the flammability of plastic materials in devices and appliances, measuring a material’s tendency to either extinguish or propagate flame once ignited. Our foams are widely used in automotive interiors, HVAC systems, industrial enclosures, and acoustic applications, providing reliable fire protection in both residential and industrial settings.